RLGs and FOGs are very accurate but are quite complex and so are relatively large and costly to manufacture. RLGs (Ring Laser Gyro) and FOGs (Fibre Optic Gyro) use the phase shift of light travelling in opposite directions around a fixed path length to detect angular velocity.

Mechanical gyros, such as DTGs (Dynamically Tuned Gyros) are still around today where high precision is needed. Gyros were originally mechanical devices which used a spinning mass supported such that its position in inertial space remains fixed thus allowing rotation of its support structure to be measured. Gyros, and their useful application for stabilising things, first emerged at the start of the 20 th Century and Silicon Sensing’s family tree dates back to these pioneering years. PinPoint ®) up to FOG-grade high performance MEMS Gyro modules (eg CRH02 and CRS39). There are now three generations of MEMS VSG Inductive, Capacitive and PZT, allowing Silicon Sensing to produce a wide range of MEMS VSG gyros from low-cost, precision, chipscale sensors (e.g. To the best of our knowledge, almost all of these gyros are still operating satisfactorily after 20 years of continuous service, testament to the reliability of VSG. Silicon Sensing produced the first MEMS VSG in the late 1990s, since then well over 20,000,000 MEMS gyros have been delivered to thousands of satisfied customers. The basic construction and principles of operation are explained briefly below. Silicon Sensing’s MEMS gyros all use the same unique patented VSG resonating ring technology to sense rotation rate through a phenomenon known as coriolis. This separates gyros from any other means of measuring rotation, such as a tachometer or potentiometer. MEMS gyroscopes, or strictly speaking MEMS angular rate sensors, are used whenever rate of turn (°/s) sensing is required without a fixed point of reference. Capacitive (VSG4) Line - 2004 to presentįind out more about our MEMS gyroscope technology.Piezoelectric (VSG5) Line - 2010 to present.Inductive (VSG3) Line - 1999 to present.

#Piezo electric gyros full#

Users should refer to the original published version of the material for the full abstract. No warranty is given about the accuracy of the copy. However, users may print, download, or email articles for individual use. Copyright of Sensors (14248220) is the property of MDPI and its content may not be copied or emailed to multiple sites or posted to a listserv without the copyright holder's express written permission.The feasibility of the high-temperature sintering method is proved by experiments.

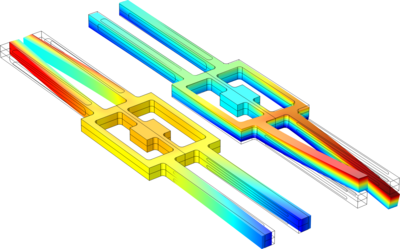

Through the open-loop and closed-loop tests, the performance parameters of gyroscope are obtained. A complete gyroscope is obtained by vacuum packaging the sintered resonator. After sintering, results of the acoustic excitation experiment and piezoelectric excitation experiment are tested, and the influence of the sintered PCEs on the CQR is determined. To achieve this goal, a novel high-temperature sintering method is proposed to combine the CQR and the PCEs, and the corresponding sintered resonators are fabricated. In order to develop a high-precision Cylindrical shell piezoelectric vibration gyroscope, it is very important to reduce the influence of the PCEs and obtain a high-quality-factor CQR. Its core components are the cylindrical quartz resonator (CQR) and the piezoelectric ceramic electrodes (PCEs).

0 kommentar(er)

0 kommentar(er)